Driveline Motors in Portable Welding Machines

Driveline motors play a crucial role in the operation of portable welding machines. These compact and powerful motors provide the necessary drive and control for various welding applications. In this comprehensive article, we will explore the different aspects of driveline motors in portable welding machines, highlighting their importance and functionality.

1. Introduction to Driveline Motors

A driveline motor, also known as a drive motor, is an essential component in a portable welding machine. It is responsible for converting electrical energy into mechanical energy, thereby driving the welding process. These motors are designed to provide high torque, precise speed control, and efficient power transmission.

2. Types of Driveline Motors

There are several types of driveline motors commonly used in portable welding machines:

-

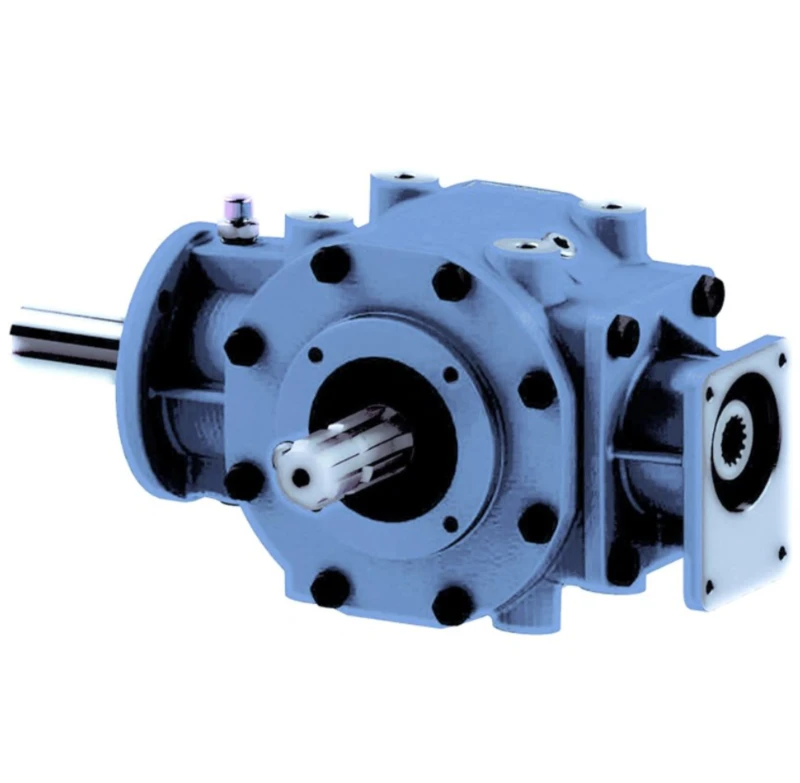

1. Bauer Gear Motor

The Bauer gear motor is a compact and durable motor that offers excellent torque and speed control. Its gear system ensures smooth operation and enhances the overall efficiency of the welding machine.

-

2. DC Motors

DC motors are widely used in portable welding machines due to their simplicity and reliability. They provide reliable performance and precise speed control, making them suitable for various welding applications.

-

3. Encoder Motor

Encoder motors offer precise position control and feedback. They incorporate an encoder that provides accurate information about the motor’s shaft position, allowing for precise control over the welding process.

-

4. Hydraulic Motors

Hydraulic motors are utilized in heavy-duty welding machines that require high power and torque. These motors utilize hydraulic fluid pressure to generate rotational motion, making them ideal for demanding welding applications.

-

5. Servo Motors

Servo motors are known for their excellent speed and position control. They offer high precision and responsiveness, enabling precise control over the welding parameters. Servo motors are widely used in advanced portable welding machines.

-

6. Brake Motor

Brake motors are equipped with an integrated braking system that ensures quick and reliable stopping of the welding machine. These motors provide enhanced safety and control during the welding process.

3. Applications of Driveline Motors in Portable Welding Machines

Driveline motors find extensive applications in portable welding machines across various industries. Some of the key applications include:

- 1. Construction and Fabrication

- 2. Automotive Repair

- 3. Shipbuilding and Marine Repairs

- 4. Pipeline Welding

- 5. Maintenance and Repair Services

These motors are essential for ensuring precise control, high efficiency, and reliable performance in these welding applications.

4. Company Introduction

Author: Czh

Our company holds a leading position in the motor market in China. We specialize in the production and distribution of a wide range of motors, including driveline motors, Bauer gear motors, DC motors, encoder motors, hydraulic motors, servo motors, brake motors, and more. With 300 sets of automatic CNC production equipment and fully automated assembly facilities, we ensure the highest quality standards and exceptional performance in our products.

We take pride in offering premium products, competitive prices, and attentive services to our valued customers. We welcome custom orders based on specific requirements. Feel free to contact us for any motor-related needs.